Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

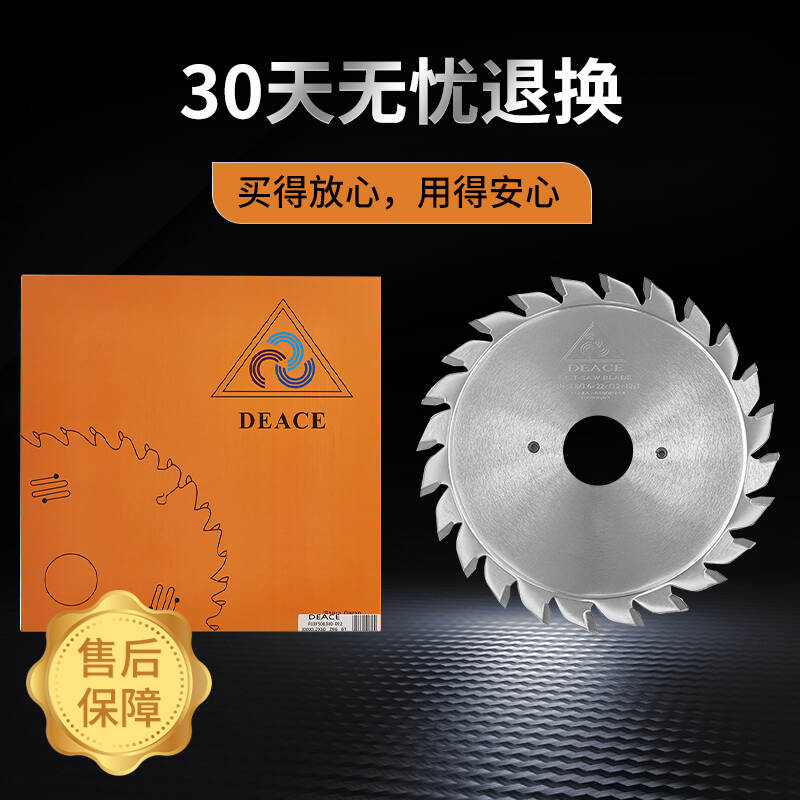

金刚石底锯类Diamond bottom saws

Applications: Mainly used in the field of woodworking, suitable for electronic precision saws, push table saws, horizontal saws and other large woodworking saw tables, with diamond large saw blades for cutting operations, can efficiently cut various wood boards such as particleboard, high and medium density board, wooden flooring, veneer panels, etc. Manufacturing process The use of advanced EDM mechanical electrolytic grinding technology makes the matrix and the cutter head form at the same time, and the whole process of mechanical standardization flow operation ensures the consistency of the production process and the stability of product quality.

-

120*2.8/3.6*20*(12+12)

-

120*2.8/3.6*22*(12+12)

-

100*2.8/3.6*20*(12+12)

-

100*2.8/3.6*22*(12+12)

-

120*3.0/4.0*20*24T

-

120*3.0/4.0*22*24T

-

160*3.3/4.3*25.4*36T

-

180*3.3/4.3*25.4*36T

-

180*3.3/4.3*30*36T

-

180*3.8/4.8*25.4*36T

-

180*3.8/4.8*30*36T

-

160*3.8/4.8*25.4*36T

-

160*3.8/4.8*30*36T

-

160*4.3/5.3*25.4*36T

-

160*4.3/5.3*30*36T

-

160*4.3/5.3*45*36T

-

180*4.3/5.3*25.4*36T

-

180*4.3/5.3*30*36T

-

180*4.3/5.3*45*36T

-

180*4.6/5.6*30*36T

-

180*4.6/5.6*45*36T

-

200*4.3/5.3*25.4*36T

-

200*4.3/5.3*45*36T

-

200*4.3/5.3*50*36T

-

200*4.6/5.6*50*36T

Materials such as high-quality alloy steel from Germany are usually used to provide stable support for the tool head and ensure the stability of the saw blade during high-speed rotation and cutting. The cutter head is made of a combination of PCD composite diamond and metal alloy powder, and through high temperature and high pressure sintering and other processes, the diamond particles are firmly embedded in the metal matrix and play a cutting role. peculiarity • High hardness and wear resistance: diamond is the hardest substance in nature, which makes the hardness of the saw blade extremely high, the Vickers hardness can reach about 10000HV, which is 50-150 times harder than carbide materials, high wear resistance, and can work continuously for 300-400 hours.• Good cutting performance: high cutting efficiency, can quickly complete the cutting of wood and other materials, and the cutting surface is smooth and flat, and the quality of one-time molding is good, which can effectively prevent wood chipping and improve processing accuracy. • Good heat dissipation and dynamic balance: Well-designed dynamic balance and scientifically crafted heat dissipation can effectively reduce the temperature of the saw blade during the cutting process, reduce the cutting error caused by thermal deformation, and extend the service life of the saw blade.