Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

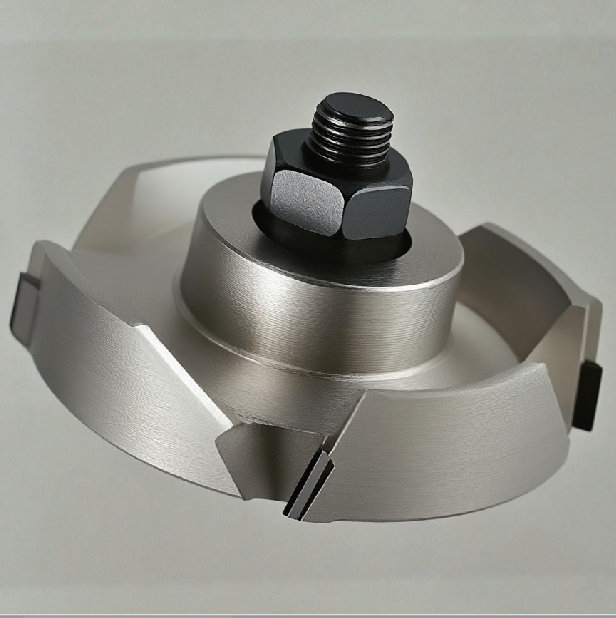

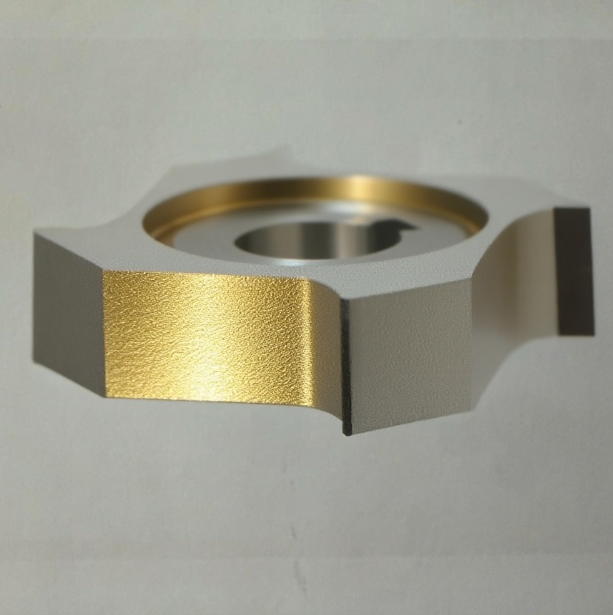

金刚石预铣刀Diamond pre-milling cutters

用于铣削三聚氰胺贴面板纸质贴面板,防火板和平面贴面板

Forjointing and rabbeting of laminatedpanel materials, papet laminated and veneered

-

125*30*63*(3+3)*3

-

125*30*43*(2+2)*3

-

125*30*34*(2+2)*3

-

100*30*48*(3+2)*3

-

100*30*45*(3+1)*3

-

80*20*50*(3+2)*3

-

80*20*35*(3+3)

-

80*20*30*(3+3)

-

180*35*63*(5+1)*4

-

180*35*43(3+1)*4

-

180*60**56*(3+3)*6

-

180*60*34*(2+2)*6

-

180*60*34*(2=2)*12

金刚石预铣刀是一种高性能的切削刀具,广泛应用于木工等行业。以下是其产品简介:

材质与结构

• 刀片材质:通常采用金刚石或PCD(聚晶金刚石)材质,其硬度高、耐磨性强,是一般合金刀具的50-80倍,能有效解决硬质合金磨损快的缺陷。

• 刀体材质:部分高端产品采用德国航空特种铝合金材质,强度高、重量轻、表面耐磨;也有刀轴采用轴承钢、刀身采用高速钢的组合,以降低成本并保证一定的强度。

产品特点

• 高精度切削:刀刃锋利且精度高,能精确地铣出各种形状和尺寸,如在家具榫卯结构制作中,可确保榫卯配合间隙极小,在木地板企口加工中能使拼接紧密贴合。

• 出色的表面质量:采用螺旋齿形设计,搭配合理的齿数与角度,加工时板材不崩边、不发黑,不起毛刺,可达到“无缝”修边效果,尤其适用于对表面质量要求高的贴面材料加工。

• 长使用寿命:金刚石刀齿耐磨,刀具寿命比传统刀具延长10倍左右,且部分产品刀片可拆装修磨,进一步降低了使用成本。

• 低噪音与高稳定性:经过严谨的生产检测,达到100%动平衡,可有效降低环境噪音,减轻电机负载,保证电机寿命,同时在高速切削时主轴磨损小,运行稳定。

应用领域

• 家具制造:用于木质板材边缘处理、榫卯结构制作、柜门与侧板加工等,为后续封边、组装工艺提供良好基础。

• 木地板加工:主要用于企口加工,还可根据设计要求铣削出特殊纹理和图案,提升木地板的美观度和安装质量。

• 木门制作:可对门芯板进行铣型,打造欧式雕花、中式线条等造型,也可用于门框的倒角和开槽处理,提高木门装配质量。

• 装饰装修工程:能对木质装饰线条和天花板造型等进行精确加工,满足高端装修对精度和表面质量的要求。

Diamond premilling cutter is a high-performance cutting tool that is widely used in woodworking and other industries. Here is a product introduction:

Material and structure:

• Blade material: Usually made of diamond or PCD (polycrystalline diamond), it has high hardness and strong wear resistance, 50-80 times that of ordinary alloy tools, and can effectively solve the defect of fast wear of cemented carbide.

• Features:

• High-precision cutting: The blade is sharp and has high precision, and can accurately mill out various shapes and sizes. For example, in the production of furniture mortise and tenon structures, it can ensure that the mortise and tenon fit is extremely small, and the splicing can be closely fit in the processing of wooden floors.

• Excellent surface quality: It adopts a spiral tooth-shaped design, with a reasonable number and angle of teeth. The board does not collapse, blacken, and has no burrs during processing, which can achieve a "seamless" edge trimming effect, especially suitable for processing veneers with high surface quality requirements.

• Long service life: Diamond knife teeth are wear-resistant, the tool life is about 10 times longer than traditional tools, and some product blades can be detached and decorated, further reducing the cost of use.

• Low noise and high stability: After rigorous production inspection, 100% dynamic balance can be achieved, which can effectively reduce ambient noise, reduce motor load, and ensure motor life. At the same time, the spindle wears less and runs stable during high-speed cutting.

Application areas:

• Furniture manufacturing: used for edge treatment of wooden boards, mortise and tenon structure production, cabinet door and side panel processing, etc., providing a good foundation for subsequent edge sealing and assembly processes.

• Wood floor processing: mainly used for enterprise processing, special textures and patterns can also be milled according to design requirements to improve the aesthetics and installation quality of wooden floors.

• Wooden door production: The door core panel can be milled to create European carving, Chinese lines and other shapes. It can also be used for chamfering and grooved processing of door frames to improve the quality of wooden door assembly.

• Decoration and decoration project: It can accurately process wooden decorative lines and ceiling shapes to meet the requirements of high-end decoration for accuracy and surface quality.